So how flat is flat enough and how do you know if a curve is good enough? Wouldn’t it be nice to have an easy answer? It’s simple enough to say throw out everything that isn’t perfectly flat or perfectly round, but most of us can’t afford to do that. That’s the answer for people who have unlimited resources. There is a little more gray area for the rest of us. Sure, you won’t always use the most optimal cane, but adjusting your scrape to the needs of the individual piece of cane can solve a lot of problems. For example, if the curve is more flat in the middle, don’t scrape as much out of the middle!

Double or Nothing’s reed-makers have a lot of experience selecting and processing cane, so we have prepared a case study of sorts to illustrate the pieces of cane we would trash and the pieces we would keep. Before we proceed, it is time for a blanket disclaimer: These are not steadfast rules. The only rule is that you have to find what works for you! The size of the cane you should use depends on an unbelievable amount of factors including the type of staples, shape, tie length, scrape, embouchure, altitude, humidity, temperature, instrument, etc. There are probably several more factors that can be added to this list. Feel free to comment and tell us about them!

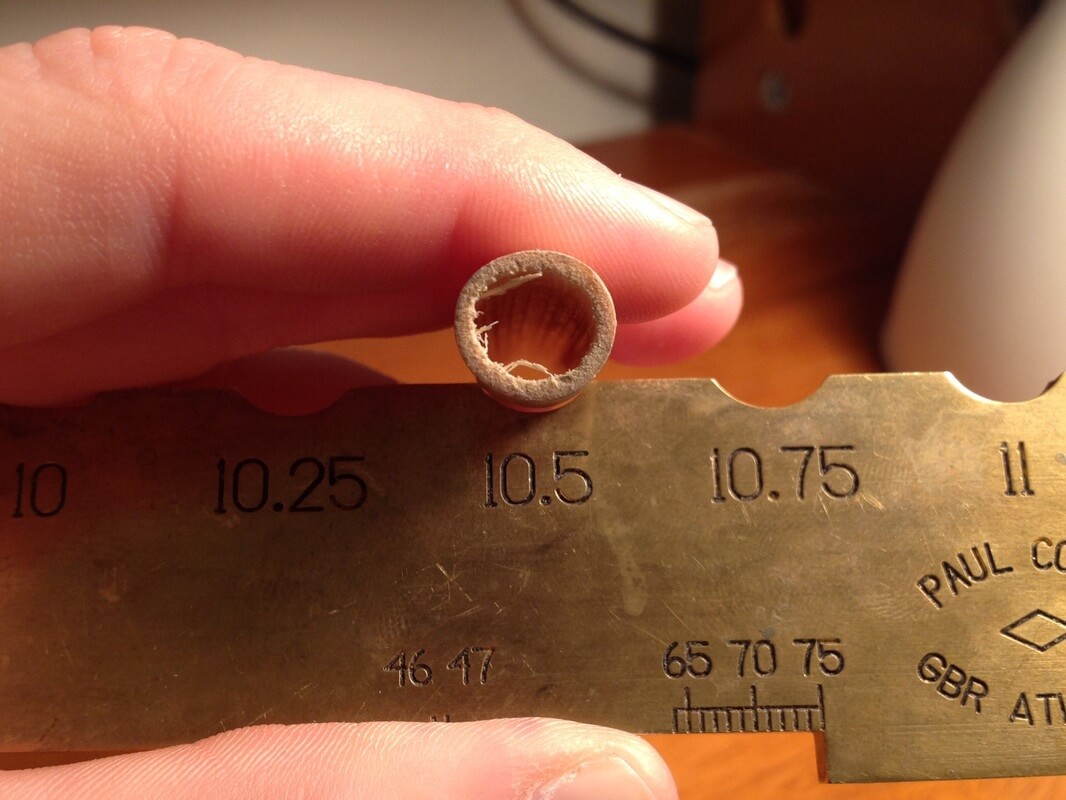

Below are three images of different pieces of cane in the 10.5 slot of the radius gauge. Everyone has a different preference, but for my personal taste, I prefer cane that fits between 10.25 and 10.5. If the cane is larger, then the opening of the reed tends to be too small. If the cane is under 10.25, then the opening

of the cane tends to be too wide, resulting in flat reeds.

This piece of cane shown above does not work the way it is currently positioned on the radius gauge. The side in question is too pointed to fit in the 10.5 slot, but the other side might be perfect! Just because one part of the curve does not fit in the radius gauge does not mean that the whole tube should be trashed. Rotate the tube a little, and you might be surprised that another part of the tube

is a good fit!

Don’t be fooled by the nice curve on this piece of cane. The space between the tube and the radius gauge tells me that this outer curve of this tube is larger than 10.5. If a wider curve works for you, than this could be a winner, but make a mental note that cane relaxes over the course of being processed. The split tube and final product will be slightly larger than during the initial measurement.

This is an example of a tube that I would split for two reasons. Firstly, the tube fits snuggly in the radius gauge which means that I won’t have to scrape to accommodate an asymmetrical curve. Secondly, the distance between the outer and inner curves is thicker than the tube in Case No. 2. This means that the cane that will be left after splitting and gouging will be more dense. This will

result in more compact veins and more focused vibrations.

Below is a close up view of a snug fit. Only round pegs have a snug fit in round holes.