Before cane processing can begin, careful and discriminatory cane selection must take place. There are a few areas in life where “discrimination” carries a less derogatory connotation. It’s okay to be prejudicial in terms of cane selection. In fact, it is important! The more you can discern between different pieces of cane, the more consistent your reeds will be.

How many oboists have exclaimed, “I love playing the oboe, but I hate making reeds!” Cane selection is one way to reduce the frustration of reed-making.

Good reeds don’t magically happen because you have sharp knives, a particular brand of staples, or the latest and greatest shaper tip. The foundation of a great reed is a good piece of cane.

There are a several reasons to practice cane discrimination:

- Inconsistent reeds and possibly inconsistent performance (This should be reason enough!)

- Frustration with the reed-making process

- Self-confidence issues: Inconsistent reeds will make you call in to question your materials, your technique, or your potential as an oboist.

- Time!!! Cane processing takes too much time to waste it on cane that won’t become a good reed. Why spend more time at the reed desk than you have to?

The most important reason is that cane discrimination will allow you more opportunities for success and will decrease your chances for failure.

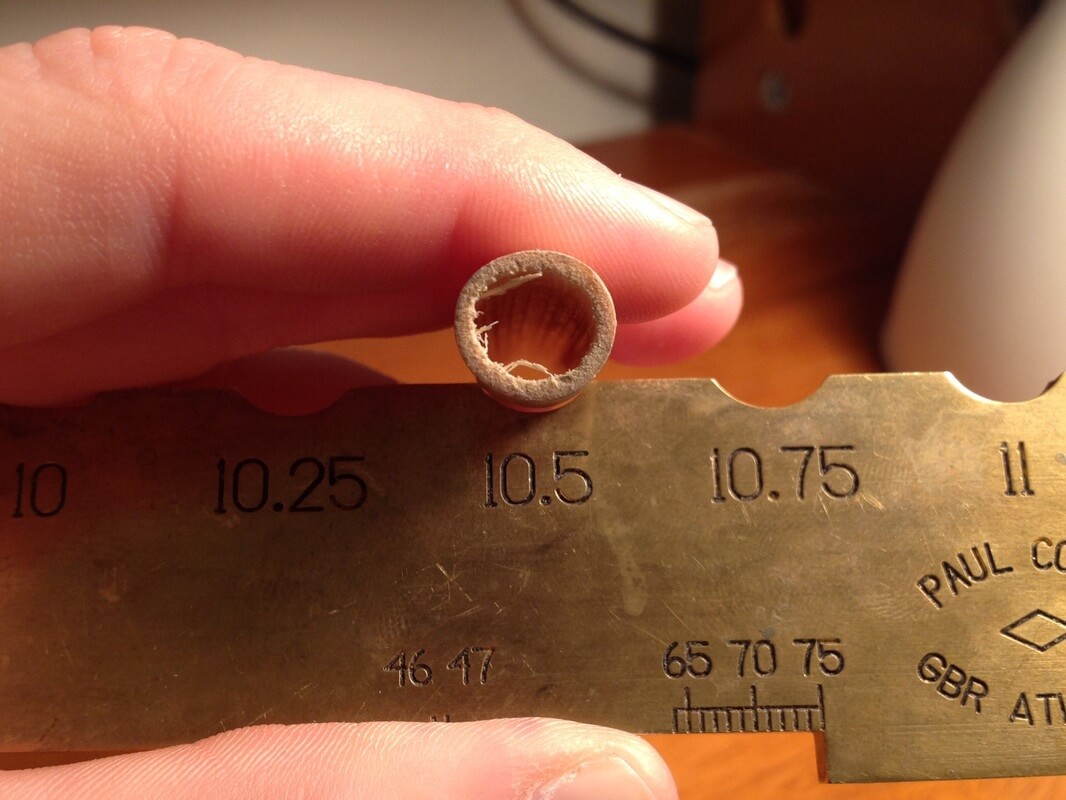

One of the most important tools necessary for cane selection is a radius gauge.

I have three radius gauges. I only use one of them to do any actual measuring. Another is the tool I’ve adopted to determine how flat a piece of cane is, and I don’t use the third at all. It’s just taking up space on my shelf.

The two shown in the picture below are the two that I use regularly. I like the Covey gauge because the curves are shallow and actually reflect the portion of the cane that I’m going to gouge. I also prefer the Covey gauge because it has increments of .25, and the one below only shows increments of .5.

I use the silver radius gauge as a flat edge to see where the cane bows or bends and that’s the only time I use it!

That’s enough radius gauge nerdiness for now! I’ve randomly selected a handful of tube cane from my bag. You can already see how different each tube is! Some are circular, some are shaped more like an oval, and there are a few with asymmetrical/pointed sides. More importantly, some of these tubes are much thicker than others, therefore, the cane is much more dense. When the veins are more compact, you are more likely to get better results. When the cane is gouged, the blade will remove cane from the inner curve. The thicker the piece of cane is, the more dense the cane will be as you approach the bark with the gouger.

The picture below shows two pieces of cane from the same bag, and there are distinct differences between the two. While neither piece is “wrong,” one of the two could be slightly more advantageous. Don’t judge the tube on the left by the gunk in the middle. The pregouger or the first few passes with the gouger will take care of the “extra” material, also known as the pulp. Notice, however, how much of a difference there is between the thickness of the two tubes. If you are good with your knives, you could probably make a decent reed from either piece of cane, but the thicker tube might give you a warmer and more focused sound because of the difference in how the veins are packed and organized.

If you want to track different pieces of cane based on their thickness, try marking the edge with a colored marker or Sharpie after you split and guillotine the cane. Mark the thicker pieces with the same color so you can objectively see whether or not there is a difference in how the reed vibrates. That’s what it ‘s all about anyway: Organizing and focusing the vibrations!

I mentioned earlier that the gouger removes cane from the inside out. Processing cane (splitting, guillotining, pre-gouging, gouging, etc.) does not change the outer curve, or the curve of the bark, so it is imperative to consider the the shape of the outer curve during the selection process. The outer curve determines how the cane will fit in the bed of the gouger. An ill-fitting piece of cane is going to leave you at the mercy of some very interesting reeds.

There are two issues to consider here:

The size of the curve of a piece of cane relative to the to the size of the bed of the gouger.

The shape of the curve of a piece of cane relative to the shape of the bed of the gouger.

A piece of cane can’t be judged based on one criteria or the other. It has to pass both tests. A beautiful curve that is too large for the bed of the gouger is going to result in a piece of cane that is too thin, and the resulting reed is predisposed to being unstable and vibrating too much. (Yes, there is such a thing as too much vibration!!!)

After identifying some potential pieces of cane with a radius gauge, the tube has to be measured and split into pieces so you can get to the optimal part of the cane. We will cover measuring and judging tubes in another installment of our cane sorting series. There’s no “correct” way to do this. Some people use a razor blade so they can be very specific in their selection, but I usually end up stabbing myself with sharp pieces of cane. Another option is shown below: a cane splitter!

A cane splitter is a fancy form of a hunting broad head on a dowel with some safety precautions, but don’t go steal the arrow out of your dad’s deer hunting equipment. That’s not sanitary, and he won’t thank you!

Oboists have put a plastic cap over the broad head to avoid injury. Insert the broad head so that the portion of the cane you want to gouge falls in between the blades.

We’ve discussed separating and storing cane in previous blog posts. This is the point where things get rough: not every piece of cane will work and not every tube will suit your needs. Most of the bag of cane will only be good for firewood. It will either be warped or end up being the wrong shape.

Check back for more thoughts on cane selection including what a good piece of cane looks like according to the radius gauge.

Julie C